Turbo Mill

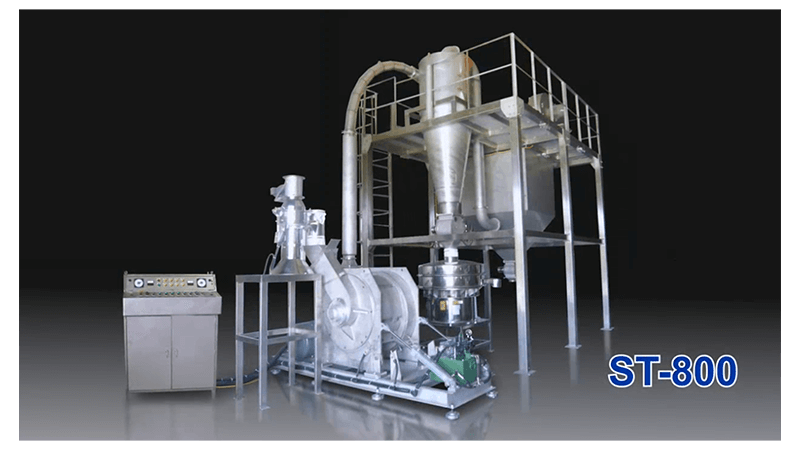

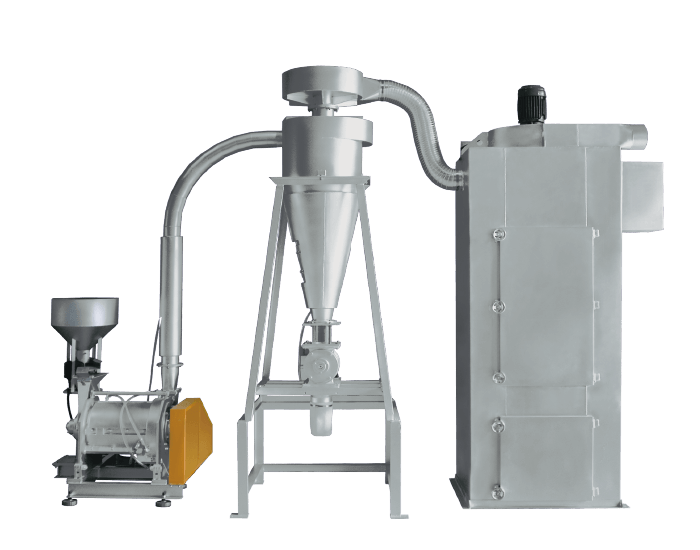

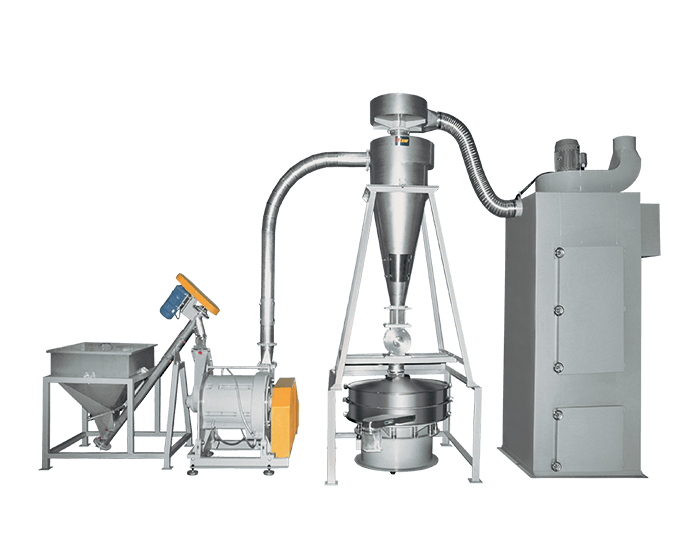

STM / STM-250 / STM-400 / STM-800

Model

Applications

Foodstuff: Rice, Salt, MSG, Sugar, Corn, Kaoliang, Agar-Agar, Ginger, Pepper, Spices, Red Bean, Soybean, Pea, Wheat, Oat, Rice Bran, Grain Powder, Fish Powder, Pearl, Banana Chip. Chemical: ABS, PE, EVA, PVC, TPE, Rubber, Calcium Carbonate, Rice Husk, Gypsum, ORE, Fertilizer, Zinc Oxide, Aluminum Oxide, Cobalt Oxide, Copper Oxide, Calcium Oxide, Titanium Oxide, Iron Oxide, Pesticides, Talcum Powder.

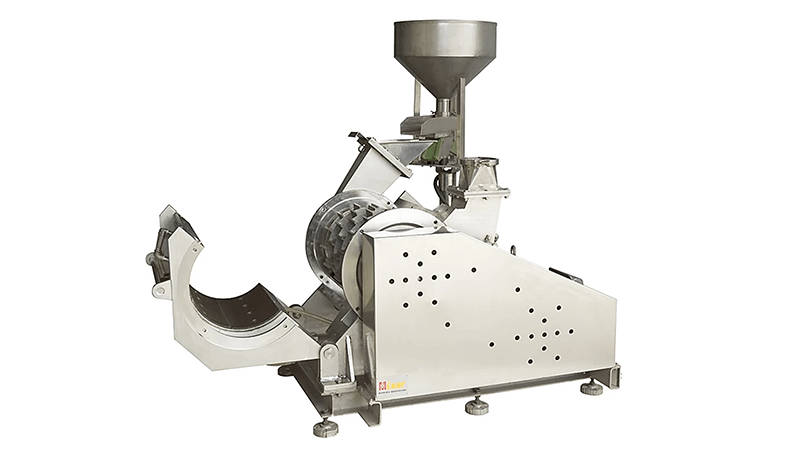

Features

- Solid Construction: The grinder has no internal screen, featuring a simple and robust design with zero malfunction for long-term use.

- Wear Resistance: Utilizing air vortex grinding minimizes contact with materials, ensuring almost no wear when processing beans and grains.

- Wide Application: The unique grinding mechanism is suitable for both organic and inorganic materials, achieving excellent fineness.

- Easy Maintenance: The upper housing can be easily opened for convenient inspection and cleaning.

- Airflow Function: The grinder’s built-in airflow and pressure system simultaneously handles material conveying during grinding.

- Labor Saving: Equipped with a quantitative feeding system to reduce manual labor.

- Sealed Structure: Fully enclosed design prevents dust leakage.

Specifications

| Model | Inner dia. of mill | RPM | Power | vol of exhaust air (m³/min) |

|---|---|---|---|---|

| STM-250 | Ø250mm(10 inches) | 4500 | 15~20 HP | 6 ~ 10 |

| STM-400 | Ø400mm(16 inches) | 3500 | 40~50 HP | 10 ~ 20 |

| STM-600 | Ø600mm(24 inches) | 2800 | 60~75 HP | 18 ~ 30 |

| STM-800 | Ø800mm(32 inches) | 2400 | 125 HP | 24 ~ 40 |

Processing capacity depends on the material being crushed.